Rotational molding, often known as rotomolding, is usually

described as a plastic process suited for forming large

hollow parts. This description was accurate 20 or 30 years

ago but does not fully describe the process today.

Rotationally molded products are a good fit for a wide

range of industries. The most common are toy and juvenile

products; industrial, agricultural, and chemical tanks;

recreational and sporting goods; and material-handling

parts such as totes, pallets, and bins.

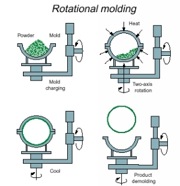

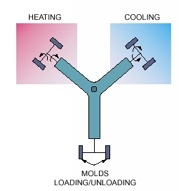

In their simplest form, rotomolding machines have three

arms that rotate between loading/unloading stations,

heating ovens, and cooling chambers. Molds made from either

sheet metal or cast aluminum mount on each arm. A

premeasured amount of powdered or liquid plastic goes in

half the mold. The mold then closes and the arm moves it

into the heating oven.

Inside the oven, the molds simultaneously rotate around two

right-angle axes. Heat fuses the resin into uniform layers

on mold surfaces. The amount of resin added controls wall

thickness. The rotating molds then move to the cooling

chamber. As a combination of air and water cools the molds

the plastic solidifies.

Parts made from different grades of polyethylene (PE)

dominate the rotomolding market. The most common grade of

PE is linear low density (LLDPE). Others include

high-density (HDPE), cross-linked (XPE), and

ethylene-vinyl-acetate (EVA) copolymers. Polyvinylchloride

(PVC) was the original material used for rotational molding

and is probably the second most common material. It can be

either liquid or powder and comes in a wide variety of

durometers. Thermoplastics such as nylon, polycarbonate

(PC), or polypropylene (PP) generally give better heat

resistance, tensile strength, and stiffness than PE.

Rotomolding is known for providing design flexibility,

low-cost tooling, and stress-free parts.

AGGRESSIVE INDUSTRIES INC.

Rotational Molding - 800.355.4093

The above diagram shows a premeasured amount of powdered or liquid plastic is placed in mold half. The mold is closed, transferred to the heating oven, and then on to the cooling station. During the entire heating and cooling process, the molds simultaneously rotate around two right-angle axes.

Above is a typical carousel rotationalmolding machine with three arms that rotate between loading/unloading stations, heating ovwens, and cooling chambers.

Copyright 2009: Aggressive Industries Inc., 8365 Sunset Rd. NE, Minneapolis, MN. 55432